Mixed volume of material:

Mixer power:

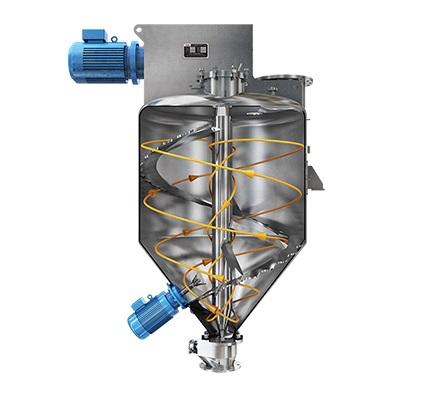

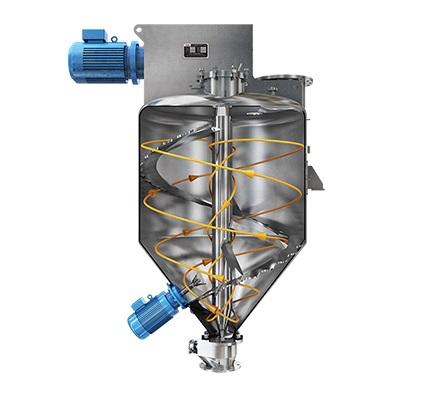

Detailed Description:

A. Cleaning of mixing parts and cylinder

The main mixing component is a vertical spiral belt; the large quick-opening door on the side makes cleaning the cylinder convenient and efficient.

B. Drive form

The mixer drive assembly and feeding port are arranged on the top of the mixer. The drive form is generally a motor directly connected to a gear reducer.

C. Pneumatic discharging

The pneumatic discharge port arranged at the bottom of the cylinder ensures clean and fast discharge with little residue.

D. Auxiliary mixing

The flying knife arranged on the side of the barrel is directly connected to the motor, which plays a role in assisting mixing and dispersing the cohesive and fast materials

E. Liquid spray pipe

The liquid spray pipe that penetrates from the main shaft of the reducer leads all the way to the center of the stirring shaft. The picture shows the rotary joint of the liquid inlet

F. Spray effect

The liquid spray pipe connected from the hollow main shaft rotates with the main shaft, so that the spray effect of the atomizing nozzle is better.

| Model L | JHVR50 | JHVR100 | JHVR300 | JHVR500 | JHVR1000 | JHVR2000 | JHVR3000 | JHVR4000 |

| Batch mixing weight kg | 20-30 | 40-80 | 120-180 | 200-300 | 400-800 | 800-1200 | 1200-1800 | 1800-2400 |

| Motor KW | 1.1 | 1.5 | 2.2 | 4 | 7.5 | 11 | 15 | 18.5 |

| Machine weight kg | 180 | 280 | 490 | 550 | 1100 | 1300 | 1800 | 2600 |

| Model M³ | JHVRM-6 | JHVRM-8 | JHVRM-10 | JHVRM-12 | JHVRM-15 | JHVRM-20 | JHVRM-25 | |

| Batch mixing weight kg | 2400-3600 | 3200-4800 | 4000-6000 | 4800-7200 | 6000-9000 | 8000-12000 | 10000-15000 | |

| Motor KW | 18.5 | 22 | 30 | 37 | 45 | 45 | 55 | |

| Machine weight kg | 2850 | 3700 | 4500 | 5000 | 5900 | 6800 | 7100 |