Mixed volume of material:10L~30000L

Mixer power:0.5KW~75KW

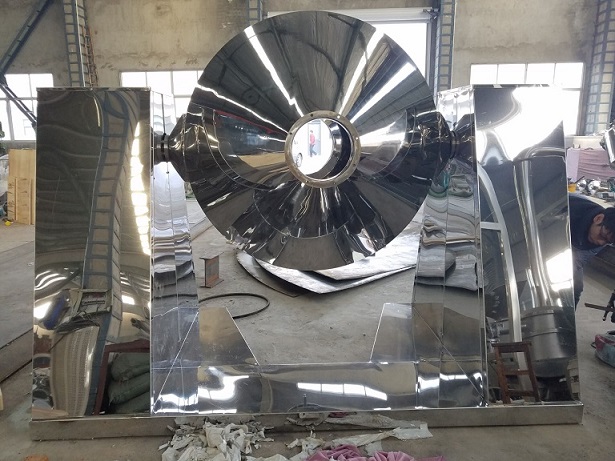

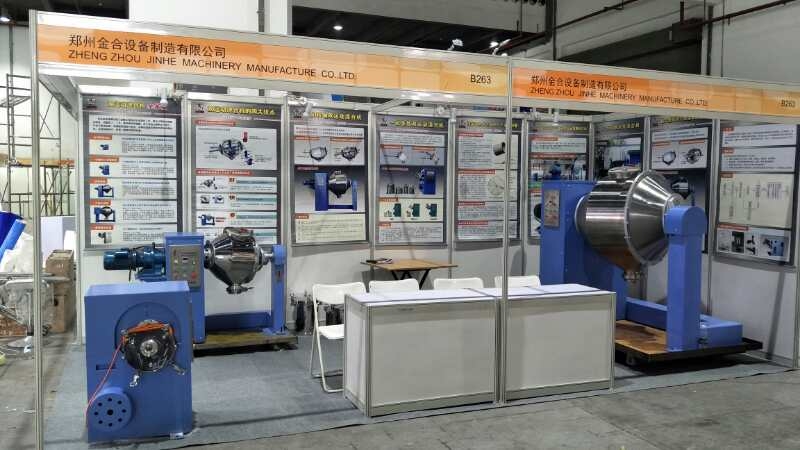

JINHE NEW factory Show

![]()

JHS-P stainless steel pharmacy mixer

Thanks for choosing our high efficiency energy-saving mixing machine. In order to preferably operate this equipment, please read this operating manual carefully before operation

Overview

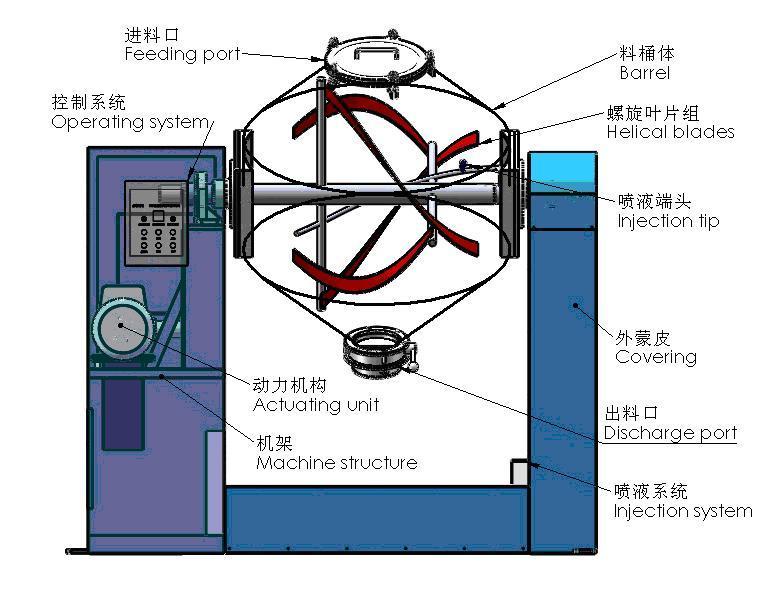

JHS-P type double cones mixer is used for several small batches mixing aggregated for a big batch in order to ensure the consistency of product performance, while small amount of fluid sprayed into powder materials. Therefore requirement for this equipment is large capacity, uniform spray fluid, operate stably, safe and convenient to use, but the requirements for mixing standard is not too high. JHS-P type double cones mixer is produced as the above requirements.

MainFeatures

This equipment adopts single movement mixing principle, inside the barrel stationary type 8 pieces of huge helical blades were designed, this will helps reduce equipment cost and improve mixing efficiency. When machine works, dry powder rolling at the bottom of barrel, helical blades’ function is make dry powder move to left and right and thus mixing completely. At the same time, as metering pump exists, fluid was uniformly sprayed into powder materials though nozzle. So by this simple rotating structure, mixing efficiency can be improved, and in the process of mixing, the sprayed fluid can be thoroughly mixed with dry powder.

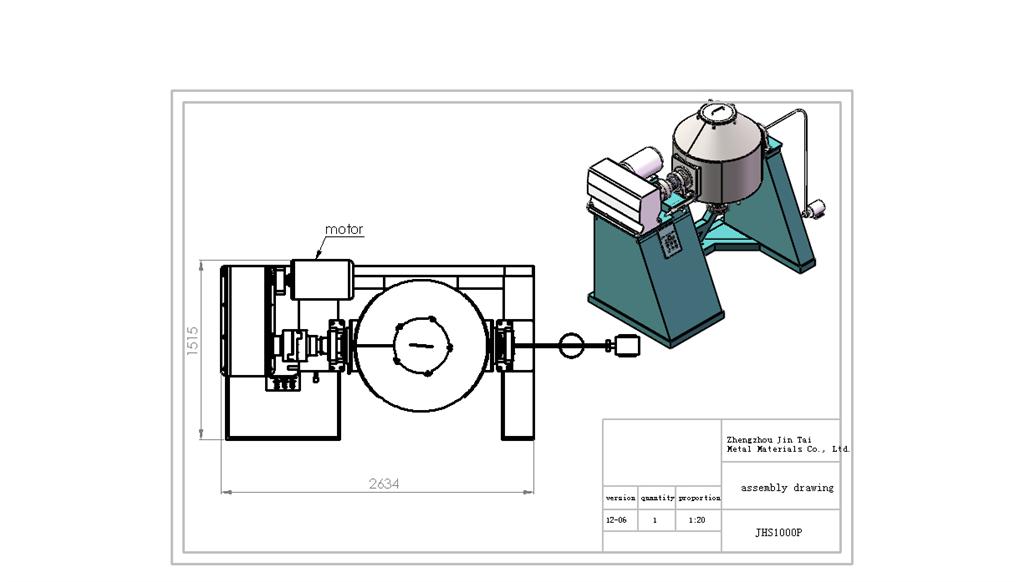

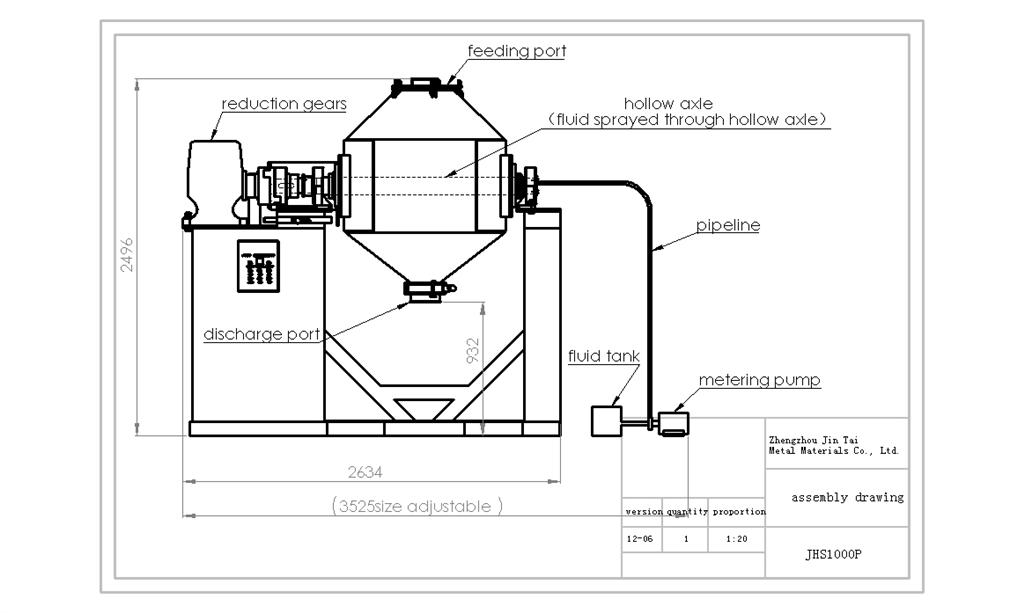

Structure Scenograph

1. Mixer Specification

| Model | Max Capacity (L) |

Max Barrel Weight Capacity (Kg) |

Barrel Wall Thickness (mm) |

Barrel Speed (r/min) |

Motor Power (KW) |

Size(mm) | Weight (kg) |

| JHS-P300 |

300 | 150 | 3 | 24 | 2.2 | 2200*1100*1650 | 450 |

| JHS-P500 |

500 | 250 | 4 | 24 | 3 | 2700*1280*1950 | 600 |

| JHS-P 1000 |

1000 | 500 | 4 | 10 | 7.5 | 2850*1420*2450 | 1400 |

| JHS-P 2000 |

2000 | 1000 | 5 | 10 | 11 | 3050*1550*2600 | 3800 |

| JHS-P 3000 |

3000 | 1500 | 6 | 8 | 18.5 | 3000*1800*3000 | 5500 |

| JHS-P 5000 |

5000 | 2500 | 6 | 6 | 30 | 4100*2100*3300 | 7800 |

| JHS-P 10000 |

10000 | 5000 | 8 | 5 | 55 | 4900*3200*4500 | 11000 |

| JHS-P 20000 |

20000 | 10000 | 8 | 4 | 75 | 5300*3400*5000 | 13000 |

| JHS-P 28000 |

28000 | 14000 | 8 | 4 | 110 | 5961*3390*5833 | 15000 |

2.Metering Pump Specification

Operating rules

1、Machine inspecting. Install the machine, adjust the barrel, be subject to rotating flexible. Barrel is a rotating part, operator should not be close to the working machine for fear be injured.

2、Loading materials. Filling powder materials through loading port, the optimum loading rate is 45%-50%. After finish filling materials, close covering cap of loading port and adjust mixing time.

3、Settle mixing time. Mixing time can be controlled by time, it should be set up well before mixer machine working. When the machine works to the preset time, it will stop automatically( during this, press stop button ,the machine can also stop working.

4、Starting up.

A、Press button “preparation” + “operate” or “shake”, the machine starts to work. This double keying operation method is for operator’s safety, prevent personal injury caused by one keying misuse.

B、 During mixer machine working, turn on the spray pump, it will spray fluid into the rotating barrel. When the fluid spray capacity meet material needs, please manually turn off power of the spray pump.

Note: This operation is independent; it is not associated with mixer machine’s working condition.

C、When the mixer machine stop working, switch on the spray pump, its working condition can be checked in real time.

5、Discharge materials. Press button “stop” to end mixing, let the discharge port rotate to the right below position by pressing “shaking” button, put a loading container at lower end of discharge port, open the valve of discharge port until all the materials discharge completely.

Fluid Injection System Operating Instructions

1. Notice

A, Before use the metering pump, please add gear lubricant to oil pointer

B, Before switch on the metering pump, make sure that the pipeline is unobstructed (valve open)

C, When the metering pump stop working, make sure that shut off the metering pump firstly, then close the fluid outlet pipe valve.

D, Outlet line pressure must be greater than the inlet line pressure.

E, Avoid metering pump pumping fluid contains solid particles.

2.Inspect working position of the fluid injection system before equipment working

A, Disconnect spray pump outlet pipe

B, Make sure that there is sufficient amount of liquid in the fluid tank.

C, Open the manual power switch of the spray pump and it begin to work independently. Observe if there is liquid outflow, if yes, it means the machine is normal. Otherwise, please detect the cause of the fault.

D, Inspect spray nozzle in the barrel clogged or not, if yes, please clean up.

3.Preparation work on the fluid spray system before mixer machine starting up

A, Adjust flow rate of fluid through manual operation rotating rod behind the liquid pump (adjust the rate between 50%-100% of the rated flow).

B, Make sure that there is sufficient amount of liquid in the fluid tank.

3rd Structure Scenograph