The working principle of vertical mixing machine is inside the mixer drum two asymmetric spiral rotation is lifting the material, turning arm slowly orbit;Outside of the spiral

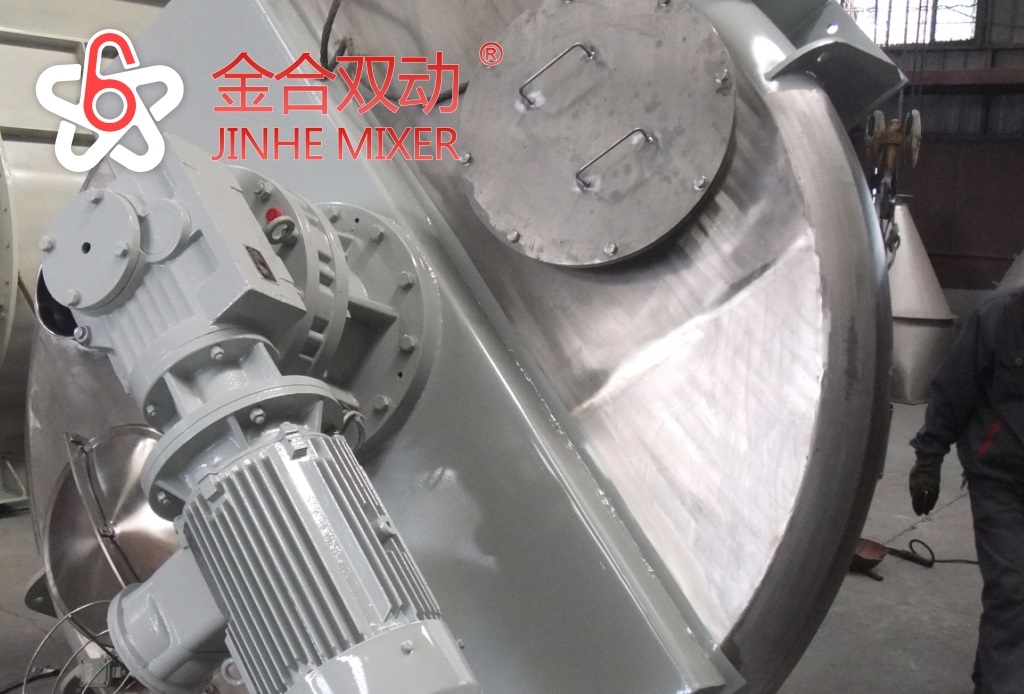

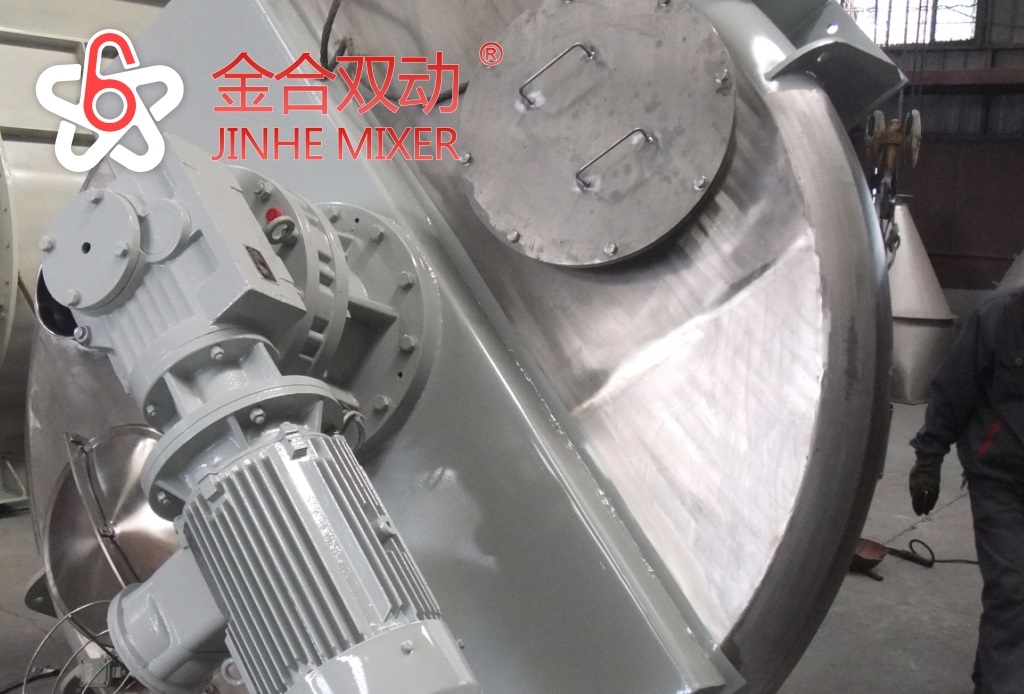

Vertical mixing machine

Into the stud material, different degree, so as to achieve full circle bearing materials constantly updated spread, the upper part of the mentioned two materials to the center again

Vertical mixing machine

Meet recesses, forming a material flow downward, added to the bottom, forming a convective circulation of triple mixed effect.The points: the form of the stirring vertical ribbon mixer, twin-screw mixing machine.

According to the technological requirements in the mixing barrel in vitro increase cooling or heating jacket, heating mode with circulation heat conduction oil (hot water) or electric heating heat conduction oil, etc.The equipment generally adopts the plum blossom shape "dislocation" valve, the valve tightly with long screw at the bottom of the joint, effectively reduce mixing blind Angle, has manual and pneumatic optional drive form;According to user needs, also can be mounted to the butterfly valve, ball valve, star discharger, and discharge, etc.

2 application scope

Widely used in chemical industry, pesticide, dye, food, feed, building materials, rare earth and other powder mixed with powder (solid - liquid).This machine for mixing materials wide adaptability, for heat-sensitive materials will not cause overheating, don't pressure feedback and grinding particle materials, the mixture will not produce specific grvity and granularity, are different points crumbs segregation phenomenon, tapered cylinder no residue for hybrid materials to meet the demand of the high.

Recommended Powder Mixing Machine:

JHX series double motion powder blender

JHN 3D laboratory dry powder blending machine

JHS chemical conical blender machine

JHRB horizontal ribbon mixer machine