Energy-saving emission reduction from the national "Eleventh Five Year" plan, national sustainable development the most important strategic plan, environmental protection and green is the synthesis of complement each other, Zhengzhou Jintai positive response to national call, pioneering the development of ideas, bold innovation, in 2007, Jintai technology design team create with a new hybrid concept and a new structure of the new type dry powder mixing machine. At the same time, both energy-saving, low consumption, environmental protection and other advantages.

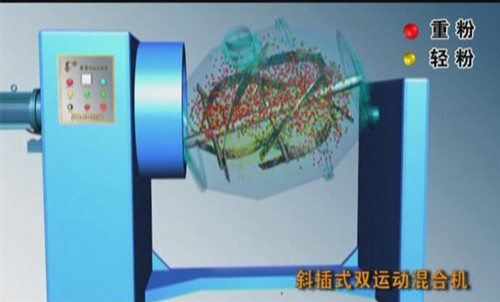

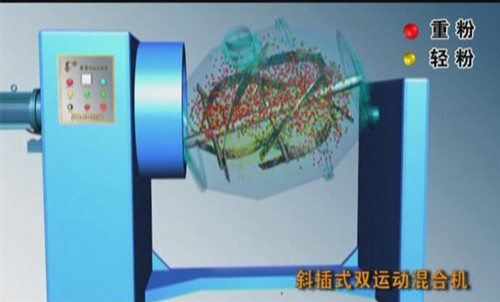

JINHE brand double movement dry powder mixing engine system, according to the national standard of energy-saving reduction motor, transmission efficiency can reach more than 98%, and traditional mixer adopts worm wheel and worm reducer, transmission efficiency is only 65%, Jintai mixing machine movement principle, two sets of motion superposition mixed, high mixing efficiency, no hard. While the traditional mixer is used in many power cylinder and the material has it, wasted a lot of energy.

A case study of the mixture of 300 kg of food additives:

V type mixer is required to use 1000L material cylinder, motor power 7.5kw

The dual movement mixer machine requires 600L material, and the motor power is only 3.0kw

| |

V type mixer |

double motion mixer |

Saving Rate |

information |

| Saving Time |

single moving |

two running system

mixing the powders |

more than 50% |

|

| Saving power |

long time |

Saving time 50%

Saving energy 20% |

50%+20% |

V type mixer

power 7.5kw

dual motion

mixer

power just

3.0kw

|

| Saving room |

large shape and taller |

the room is just 50%

compare with

V mixer machine |

More than 50% |

|

| Saving cost |

higher power energy cost |

Saving energy

more than 50% |

30% |

|

| Saving |

The feeding port is very high,

it use big dum |

smaller drum and

lower container |

lower drum |

|