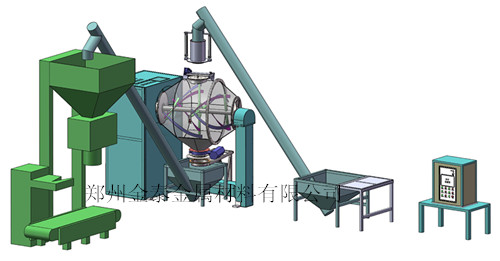

With the development of modern machinery industry, the use of dry powder mixing machine is more and more wide, the labor cost is higher and higher. The so-called automatic production line, which is from the raw material processing - dry powder mixed - packaging process to achieve automation, clean and clean, through the PLC programming control, combined with the actual production process, integration. The biggest advantage is that the use of fewer people, high degree of automation, reduce the cost of employing and management costs, improve production efficiency.

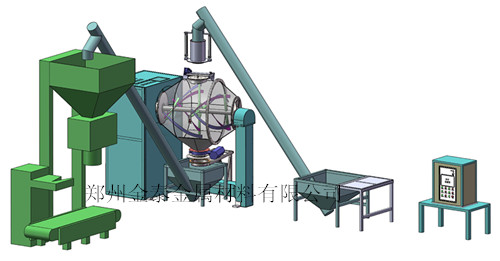

The new type of gold and the new type of double motion dry powder mixing machine, with its unique dual motion design concept, completely solve the traditional dry mixed machine material mixed with uneven, mixed time, material weight powder is difficult to mix, fake particles difficult to mix and so difficult to solve the mixed problem.

As an important part of the automatic production line, the mixed effect of dry mixed machine directly affects the final product quality. The new type of dual movement dry powder mixer combines its structure features. It can achieve the perfect combination of upstream and downstream equipment.